Two farmers designed and built a centre pivot wheel that won’t deteriorate in the sun and can’t go flat or burst.

It’s always bothered Mr. Ampie Venter from Orania in South Africa that a centre pivot irrigation system’s tyres are forever being damaged by the sun.

“The tread of the tyre is still in top condition when it starts to crack from sun and water exposure. What actually happens is that the tread forms tiny cracks through which the sprinklers force water. It weakens the rest of the tyre until it can’t carry the load anymore and bursts. Millions are wasted every year on replacing these wheels that get burnt in the African sun,” says Ampie.

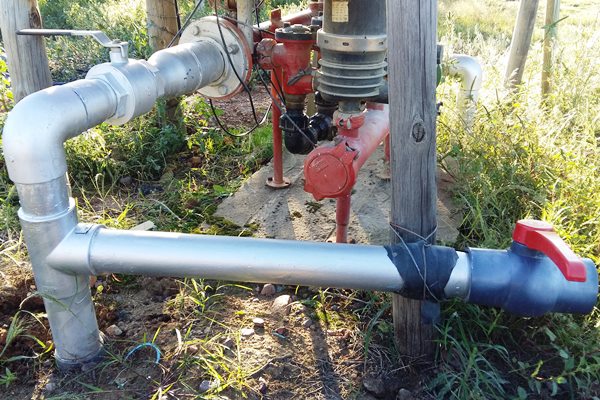

To prevent this, he and a Mr. Piet Potgieter, a retired engineer, designed a special step wheel for pivot points. In reality the ‘wheel’ consists of 12 rectangular containers welded together in a wheel form. The containers run flat on the ground like the chains of a caterpillar, so that it doesn’t form a ditch. This is different to rubber tyres, which force the ground to the outside and creates a deep ditch that causes flooding on angled surfaces.

The wheel is designed in such a way that it fits the hub of any brand or model of centre pivot. The two halves of the wheel are bolted onto the hub so that the farmer won’t have to replace the hub. The step wheel also prevents the damage that might be caused if a tyre bursts in the night and the irrigation system goes off course or falls over.

Ampie says building the prototype for the wheel was much cheaper than a rubber tyre. Because the wheel moves so slowly, aluminium or stainless steel can also be used, which would make it lightweight and durable.

Contact: Ampie Venter – ampieventer@gmail.com.